Asset reusability

When planning your power transition, it’s important to factor in how it will impact your current and future asset base. In general, the best-case scenario for your business and the environment alike will be one in which your current assets can be reused with as low overhaul efforts as possible. Reusing assets reduces the overall costs per asset, reduces disruption to your operations, accelerate your energy transition and strengthens brand consistency. It is more than just a cost-saving measure , it is also a strategy to create more value from every investment.

Surprisingly, the possibility of reusing and /or repurposing assets is often ignored or overlooked as factors in the decision making process, even though it can often maximize value in energy transition projects. Traditionally, it has been common practice to replace existing equipment and systems with new ones in energy projects, the assumption being that this minimises risk. Indeed, reusing assets requires that design and construction engineers work closely together on solutions that will maximize existing asset utility. Reducing risks associated with extending the lifecycle of existing assets is important. Therefore conducting thorough tests and assessments that ensure the quality and integrity of the existing assets are required.

We argue that although reusing and repurposing does require careful planning and attention, the many benefits in terms of costs, risk, speed and reputation will outweigh the costs in most cases. Once risk has been properly mitigated and quality verified, there are great benefits to reusing or repurposing existing assets.

Some advantages of reusing existing assets include:

- Maximized outcomes. Organizational objectives and goals can be maximized by optimizing the use of existing assets within new (renewable energy) systems. Basically you do more with less.

- Reduced disruption. Reusing or repurposing assets is less disruptive to your operations since it eliminates the need to break down and replace current assets and systems. Reusing or repurposing assets causes less disruption to facilities and their occupants and are therefore the fastest and most cost efficient option.

- Easier change management. System operators, already familiar with existing systems, do not have to relearn entirely new components, reducing the learning curve associated with energy modernization projects. This leads to a quicker transition, easier adoption and higher cost efficiency.

- Compressed project timeline. Even if the reused or repurposed assets require disruptive processes that add to the project timeline, investing in the planning and design effort upfront reduces the implementation timeline. As a result your energy transition will be the quickest option available, allowing you to get back to business faster.

- Sustainability. By reusing or repurposing existing assets, the project’s environmental impact is reduced. This strategy avoids having to dispose of useful assets and eliminates the environmental footprint created by the manufacture, packaging, and installation of unnecessary new equipment.

Factors that influence asset reusability

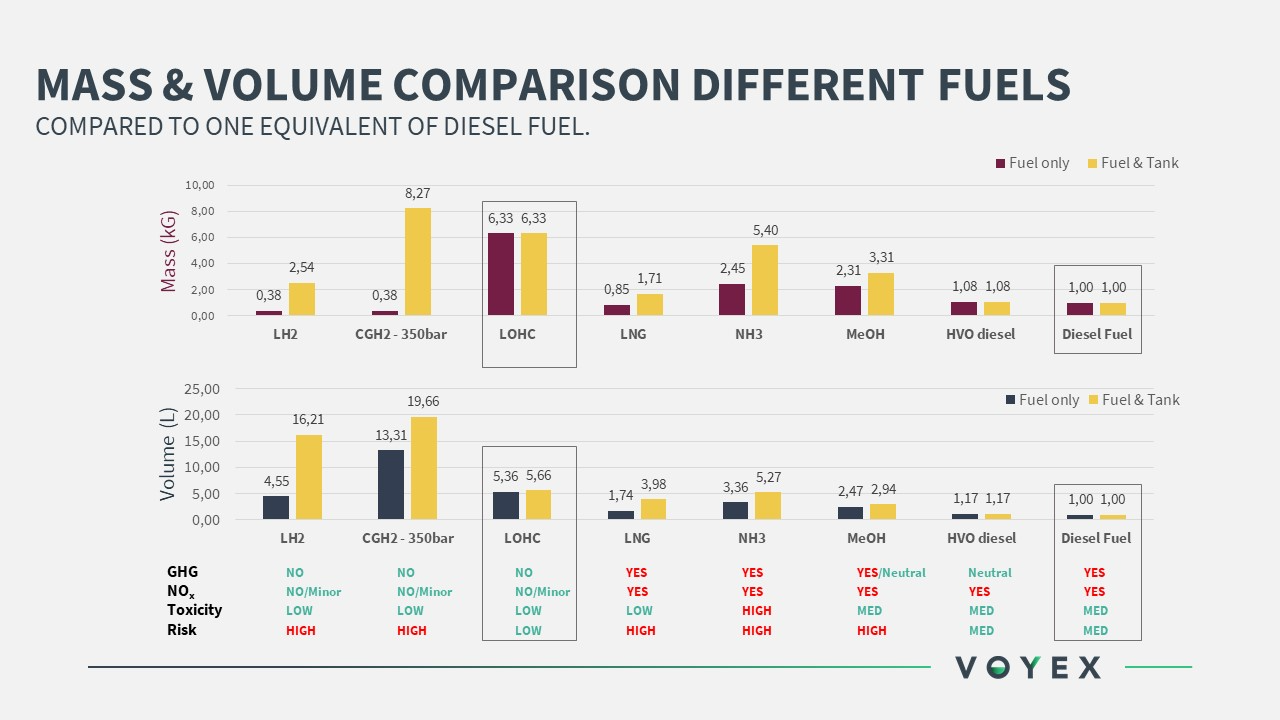

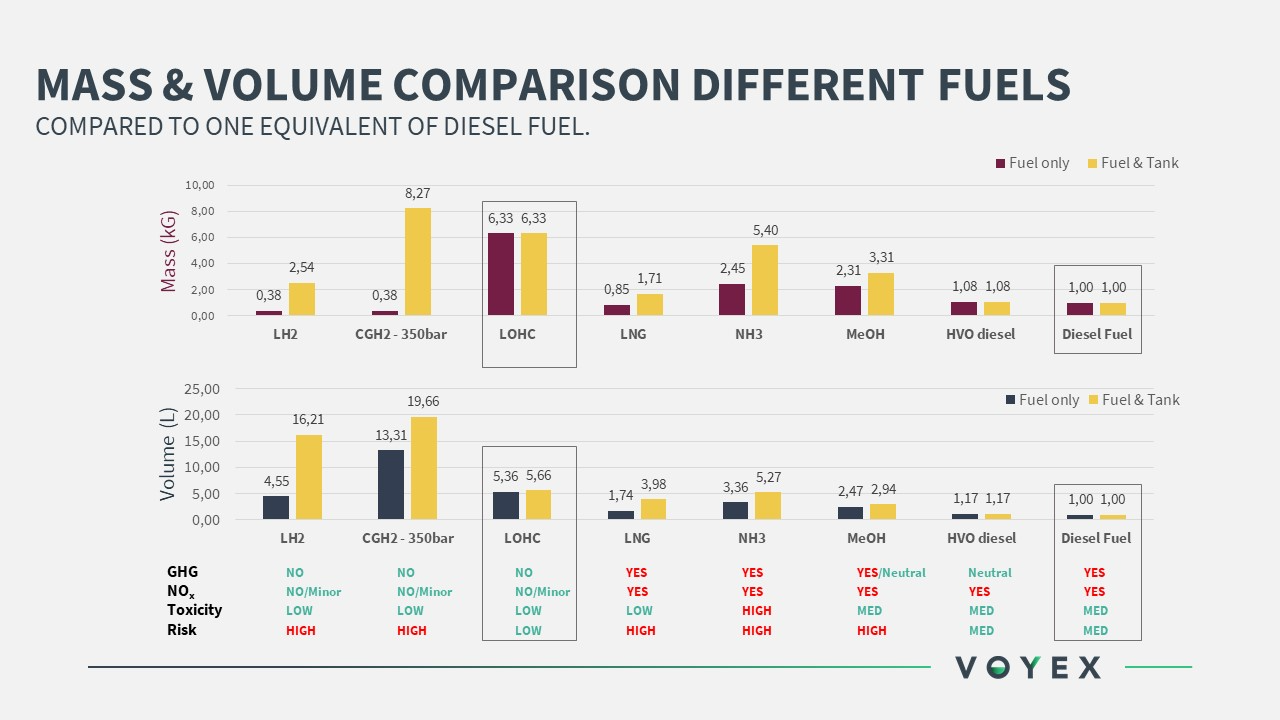

The diesel days are coming to an end and a variety of zero-emission alternatives are entering the stage. The winning alternatives will contain many of the good qualities that diesel brings, but without the emissions. Voyex LOHC is safer than diesel with respect to its higher flashpoint and toxicity, and can practically be considered a drop-in replacement for diesel. Furthermore, Voyex LOHC is non-corrosive, non-explosive and non-combustable and can therefore be handled and stored in similar conditions as diesel. In other words, your assets can be reused with minimum overhaul. Compared to alternative zero-emission fuels, Voyex LOHC comes out as the winning contestant on aspects such as safety and toxicity, which determine reusability of your assets most (see graph below).

Based on these findings, Voyex LOHC requires the lowest investments for reusing existing diesel infrastructure, limiting CAPEX/investment costs related to the transition from diesel to a zero-emission (hydrogen) energy system across the supply chain.

Voyex B.V has developed a Liquid Organic Hydrogen Carrier that will make the transition from diesel to zero-emissions as easy as it gets. We work closely together with many partners in the hydrogen supply chain to help get the zero-emission economy off the ground as fast as possible. Contact us for more information or sign up for our newsletter!